V&N Glass - a Case Study

What was the big problem that needed to be solved?

V&N Glass is Sydney’s leading glass processor and decorative glass supplier. The business custom cuts and processes all types of glass in their Wetherill Park factory where heavy machinery runs from 6 am until 6 pm, Monday to Friday.

The intensive machine work and long hours of operation create very high electricity bills. Add in the fact that the business is operating predominantly in sunlight hours and V&N Glass becomes the perfect customer for a solar PV solution.

Figure 1: Part of V&N Glass' Manufacturing and Processing Plant

What is SEA trying to achieve for the end customer?

SEA’s goal was to offset the electricity cost as much as we could. The key solution was to size the system appropriately so that V&N could offset their huge daily power use as much as possible. This solution also met with the business owner’s vision for a more sustainable future for our planet.

Is this a problem that is common to the customer’s industry?

This is a common problem in the glass industry and across the entire manufacturing sector where the daytime running of heavy machinery is involved.

What are the market drivers that are relevant to this installation – (subsidies, STCs/LGC’s, self-consumption, tax write-offs, etc.)?

The initial discussion was around a smaller budget and we looked at a 100-kW system which would be entitled to STCs. However, after a comprehensive analysis of the customer’s seasonal consumption pattern over a number of years, it was clear that a much larger solution was necessary. V&N agreed that a 500-kW installation was more realistic for their needs and they were pleased that the LGC’s were available to greatly subsidize the overall cost of the project.

Consider why you are writing this case study – are you trying to approach a specific business segment – then refer to this segment in the challenge.

SEA is targeting the glass industry specifically but also working hard to impact the entire industrial sector. SEA is among the leading experts in industrial solar PV and has over 3,000 installations across the commercial and high-end residential space. From small to uniquely complex solar systems, SEA’s differentiator is to design an end-to-end customized solution backed by a Return on Investment guarantee and the longest warranties. Our solutions are implemented seamlessly by our very own engineers and installation teams, no subcontractors involved.

The Solution

What solution did you provide? Inverters, optimisers, modules?

We came up with an undeniably high-quality solution, providing the best technology available in today’s market - LG NeON 2 panels matched to SolarEdge inverters and optimisers.

The LG NeON 2 panels have unique patented technology which make them incredibly efficient compared to standard panels. First-class materials and a highly durable design, combined with outstanding quality control, gives LG the confidence to offer an industry-leading 25-year full replacement warranty.

SolarEdge offers a brilliant solution for maximizing system performance coupled with the best monitoring tools available. Every 2 panels have a dedicated optimiser to maintain optimal power output and provide live reporting on panel performance. Any issues across the entire 1,200 panel installation can be easily pinpointed on the SolarEdge monitoring portal and rectified. There is no need to lift entire rows of panels to find a fault, as is the case with conventional string inverter systems.

Furthermore, SolarEdge optimisers offer an unprecedented level of safety with panel-level shutdown if there is a dangerous electrical fault, and the optimisers come with a 25-year warranty which is 15 years more than their nearest competitor. The customer was extremely pleased with the assurance offered by such long product warranties on both the panels and optimisers.

Why was SEA chosen for this installation?

SEA was carefully vetted against 10 other solar providers. We were awarded the project based on our value for money, leading technologies, long-term warranties, and our proven and extensive commercial installation experience.

V&N is a family concern founded 30 years ago by Tony Nguyen who continues to oversee all aspects of the business. Apart from the impressive savings on electricity bills, Tony wanted to incorporate a renewable energy source as a legacy for his sons and a contribution to a more sustainable planet.

It was clear to SEA’s Director of Business Development, Daniel Lanzetta, that Tony was after long-term value for money, not necessarily the cheapest purchase, but a system with the lowest cost of ownership. With this in mind, Daniel worked closely with Tony to gain an in-depth understanding of the energy needs of the business both currently and to cover future expansion. SEA dedicated extensive hours, 3 times more than an average commercial project, to ensure that every detail of Tony’s vision was analysed and considered for the final customized proposal.

More than simply offering the LG and SolarEdge components off the shelf, SEA teamed up with designers and engineers from those companies to develop a top-notch system configured to produce maximum performance and longevity.

Having strong partnerships with the best brands certainly influenced Tony to select SEA for the installation. However, it was decisive that SEA has an excellent reputation and a solid establishment in Sydney, and the ability to deliver an end-to-end solution with its own employees, not subcontractors or third parties. SEA was 100% responsible for ensuring a seamless experience from start to finish with ongoing no-cost support and a 10 Year Workmanship Guarantee.

V&N could see in practical ways how SEA’s core values are applied to our everyday actions, from the first client visit to the final proposal and subsequent service delivery. SEA champions the need for integrity, dedication, enthusiasm, social awareness and innovation. Every one of these values was included in V&N’s solution.

What were the initial drivers that drove the customer to install solar (financial, regulations) Did this customer have any previous experience with solar?

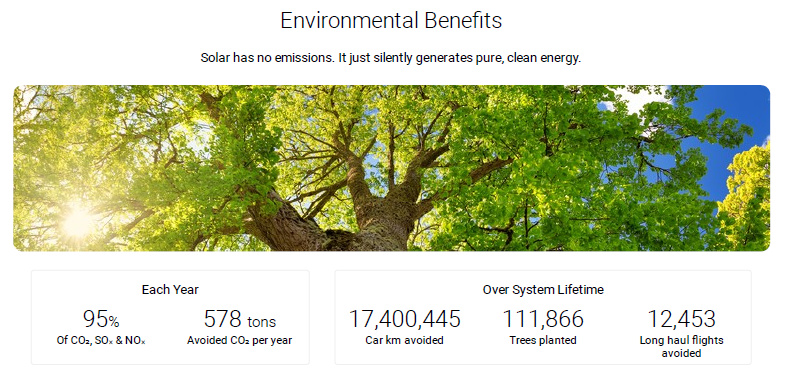

V&N management did not have any experience with solar energy solutions. However, the ever-increasing cost of electricity was severely impacting the company’s bottom line. They did their research and solar PV was the obvious and most cost-effective solution. Solar PV also appealed because of the clear environmental benefits by reducing reliance on energy derived from fossil fuels.

What benefits can you quantify? kWh of power produced, expected ROI, Financial savings etc.

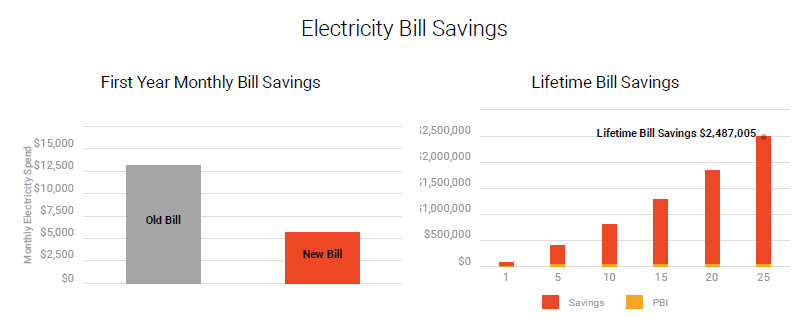

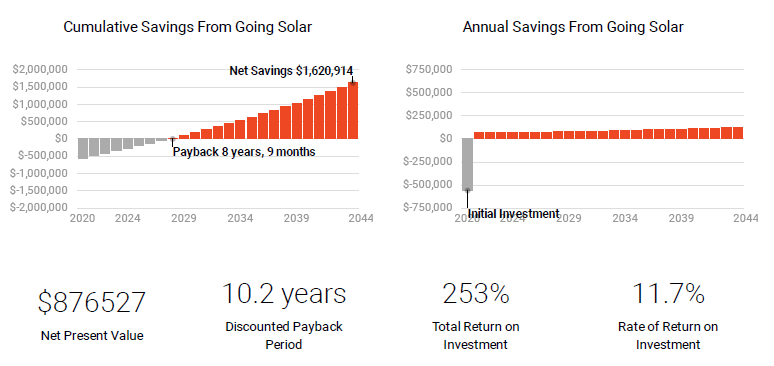

This system is projected to have a 9-year payback period, decrease reliance on the electricity grid by 60%, and provide a 25-year electricity bill saving of $2.5 million.

Other Considerations

-

What were the shading impacts like?

No shade impact detected.

-

Was there any thermal mismatch cause by a prevailing wind at one end of the site? Is panel soiling likely to be an issue?

Neither factor will be an issue in accordance with the system design.

-

Where you able to add more modules to this site because of SE flexibility?

The SolarEdge solution allowed flexibility with the system layout by enabling SEA to install more panels around minor obstructions.

-

Was a PVsyst report done? Results?

N/A

-

Safety – was this a factor and was the customer aware – does the building have flammable contents?

No highly flammable contents. Every aspect of safety was covered in the project design and all relevant Australian Standards have been met.

Fast Facts

499.66 kW total PV capacity

1,204 x 415W LG NeON 2 panels

5 x SolarEdge 82.8 kW inverters:

602 x P800 power optimisers

System Hardware

- LG NeON® 2 (Commercial)

- 199.660 kW of Solar Power

- 1204 x LG415N2W-V5

- LG NeON® 2 415 Watt panels

- 25 Year LG Product and Performance Warranty

- Up to 20% Module Efficiency

- 705,088 kWh per year

Cleanergy 'PV-ezRack' Mounting System

- 10 year manufacturer's warranty

- 1x Cleanergy 'PV-ezRack' Mounting System

Inverter

- SolarEdge 414.000kW Total Inverter Rating

- 5 x SE82.8K

Grid Protection Board

- Grid Protection Board Installation

- 1x GPB

Engineering Certificate

- Structural Engineer Assessment and Certification

- 1 x EGC

Quote

A statement from the system owner, eg, by choosing SolarEdge we were able to improve our energy yield by more than xx % and with their detailed monitoring, we can track individual panel performance to better understand the savings generated from our investment. Their SafeDC technology also meant we have state of the art protection against any fire hazards.”

%20(1).png?width=265&height=96&name=www.smartenergyanswers.com.auhs-fshubfsSmart%20Energy%20Answers%20Logo%20(HIRES)%20(1).png)

.png?width=514&height=121&name=Tesla%20Powerwall%203%20(new).png)

.webp?width=300&height=180&name=sigenergy-gold-installer-300x180%20(1).webp)